We are Manufacturer, Supplier of Rotary SPM Machines from Kolhapur, Maharashtra, India.

A rotary SPM (Special Purpose Machine) for drilling grease nipple holes is a specialized piece of equipment designed for a specific manufacturing or assembly process. Grease nipples, also known as grease fittings or zerk fittings, are used in mechanical systems to facilitate lubrication. Here's a basic outline of what a rotary SPM machine for grease nipple drilling might involve:

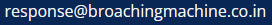

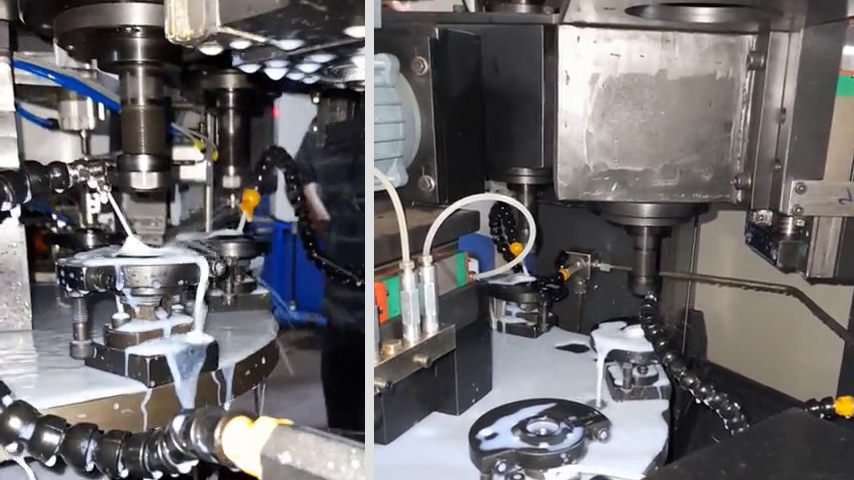

The machine is likely to have a rotary mechanism that can rotate the work piece &Its clamping fixture allowing precise positioning for drilling holes. This can be achieved by using Indexing Table or Servo table available in market. Define the sequence of operation to be done. Accordingly plan these operation stations on rotary table & place the Drilling unit / other machining process unit at the position.

The drilling unit would include a spindle or drill head designed for drilling holes of the required size for grease nipples. The drilling unit should be adjustable to accommodate different workpiece sizes and configurations.

A control system would be integrated into the machine to manage the rotary motion and drilling process.The control system may include programmable logic controllers (PLCs) or computer numerical control (CNC) systems for precise and automated operation.

There might be a feeding system for presenting the work pieces to the work holding fixtures. Rotary Bowl feeder is used to feed the jobs in to the fixture mounted on rotary table. It enable manless machine working with high accuracy & productivity.

If the machine is designed to handle different types or sizes of grease nipples, there might be a tool change mechanism to switch between drilling tools easily.

In High production machine job unloading also bottleneck if it depends on human intervention. So for High productivity Unloading the job & collecting in separate tray in done automatically by ejecting & collecting system. This enable to run the machine without Human intervention.

Depending on the materials being drilled, a coolant system may be incorporated to manage heat generated during the drilling process.

Safety features such as emergency stop buttons, protective enclosures, and sensors to ensure safe operation.

Some machines may include sensors or cameras for quality control, ensuring that each drilled hole meets the required specifications.

The machine may have features that facilitate easy maintenance, such as accessible components and diagnostic tools. Also machine alarm system for self-fault finding is incorporated in HMI unit.

The machine may be customizable based on the specific requirements of the manufacturing process it is intended for. It's important to note that the exact design and features of a rotary SPM for grease nipple drilling can vary depending on the specific needs of the manufacturing process and the types of materials being used. Additionally, consulting with a manufacturing or automation engineering expert would be beneficial for tailoring the machine to your specific requirements.